Understanding Gear Reduction: Types, Purposes, And Advantages By Fabian David H

Machining methods and different gear forming methods aren’t that viable in instances of huge diameters. Therefore, you’ll find it simpler to keep up precision during gear manufacturing. Spur gears even have little to no axial load, so they are fairly efficient for a gear practice the place you want to minimize mechanical losses.

The ongoing quest for quieter drives has been a powerful impetus in advancing plastic gear design, particularly in cars, houses, and offices. This has led to using extra lubricious or versatile polymers, improved precision, and new tooth shapes. In the latter case, plastic readily creates unique profiles, similar to tooth having varying stress angles, which reduce transmission noise and energy, particularly at low energy. The progress in the measurement and power of plastic gears are good examples of the progress made over time. When plastic gears first emerged into broad use in the Sixties, they were sometimes smaller than 2 inches and had power levels zero.25 HP.

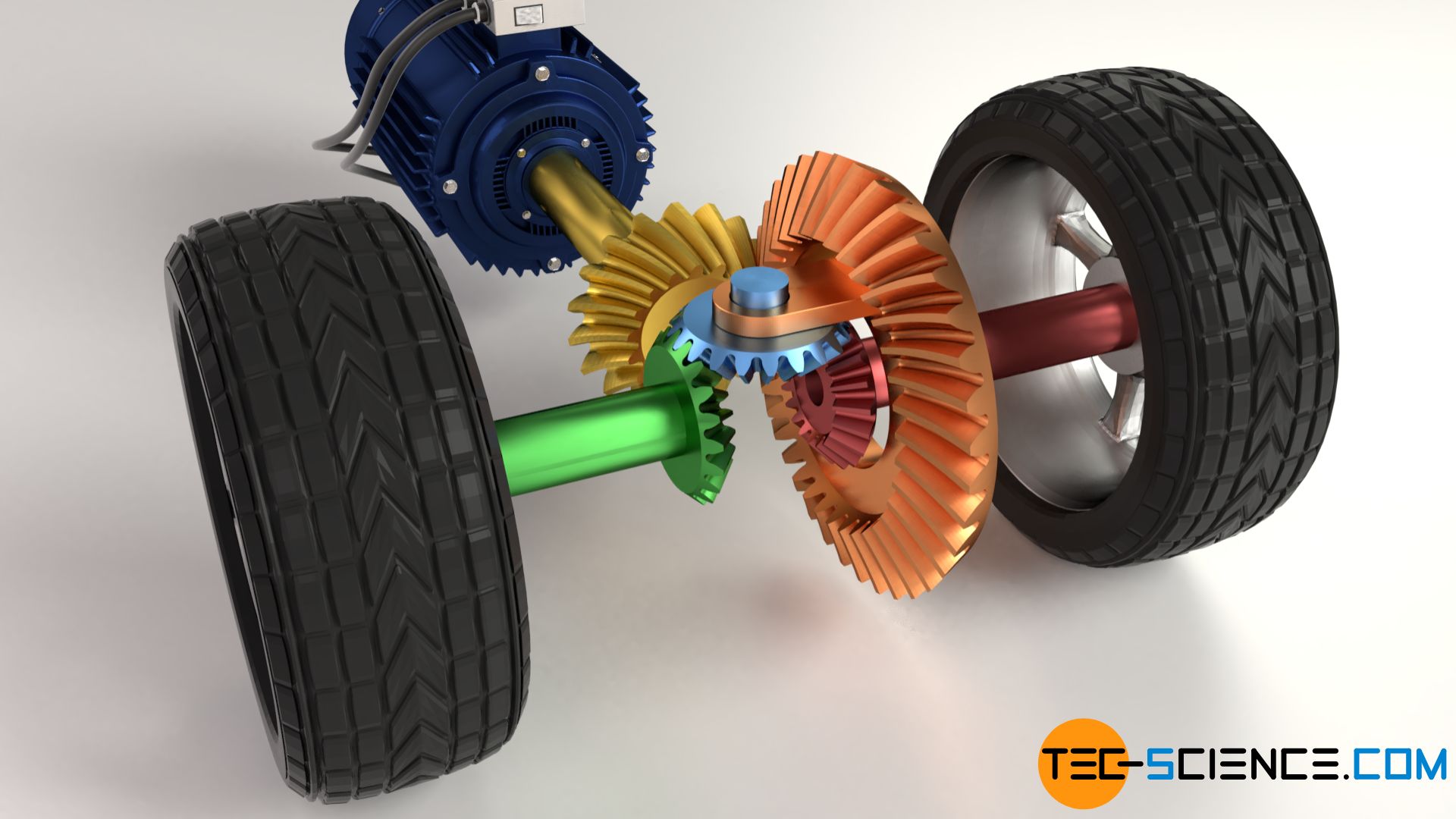

Automotive Gears

Figure 5 Average precision and recall of the 10-folds for the broken tooth defects. Average precision and recall of the 10-folds for the broken tooth defects. Probably the obvious opportunities for gear manufacturers instantly are to use AM know-how to design and print customized aids, instruments, jigs, and different solutions in-house to scale back current improvement occasions. Because of comparable drivers in other industries, production of steel AM techniques and materials offered into AM have been growing at higher than 20 % compound annual rate since 2014.

Types Of Automotive Gears

The odd-side clutch disengages as the even-side gear prepare engages, leading to nearly instantaneous shifts. Considering its lately rising popularity amongst automakers, the constantly variable computerized transmission might look like new know-how to some. However, Leonardo da Vinci had already drawn plans for a rudimentary model of it over 500 years ago. Of course, modern CVT variations are far more advanced than da Vinci’s designs. Polycarbonate, for instance, isn’t a good gear material due to its poor chemical resistance, lubricity, and fatigue properties.

They are also very dependable, which is why producers like Nissan and Toyota use CVTs of their automobiles. The market for gear techniques covers quite so much of gear types which would possibly be essential for power transmission and movement regulation in autos. This phase is generating significant demand owing to escalating car manufacturing, enhanced fuel economic system, and a heightened focus on efficiency. Material selection is important in automotive gear design to make sure sturdiness, effectivity, and weight discount.

The DSG transmission works just like a motorcycle’s wet multi-clutch plate. The DSG transmission is licensed under the name of Volkswagen Group and utilized by autos beneath the group. Manufacturers like Audi, Bugatti, Lamborghini and Volkswagen use their versions of the DSG transmission in most of their cars, just like the Audi A4, Bugatti Veyron and Lamborghini Huracan. One clutch controls the odd numbered gears whereas the other controls the even numbered gears. For example, when first gear is engaged, the odd clutch is in use, and the even clutch pre-selects the second gear, which permits continuous shifts without interrupting the ability circulate from engine to the transmission.

To meet these targets, the European authorities has initiated varied projects aimed at establishing regional pricing constructions for EVs. The automotive gear market was valued at USD 5.seventy nine billion in 2023 and is predicted to achieve USD 10.27 billion by 2032, rising a CAGR of over 6.58% during the forecast period. The top highly demanding automotive gearbox producer and provider is Bharat Gear. To attain the 50% of the auto element enterprise that isn’t currently automotive gears served by the Mumbra plant’s unique OEM clients, BGL determined to increase into the substitute market. Because it is the most important component of the machine, selecting a vehicle gear product provider and manufacturer with extensive knowledge is critical. It’s troublesome to choose the most effective auto gear producer in India as a outcome of there are so much of of them.

The drive pulley is connected to the facility input, while the driven pulley is linked to the wheels. The transmission is managed by a computer, which selects the correct gear based on input from sensors across the automobile. This system usually includes an overdrive gear, which helps to improve gasoline efficiency by lowering engine drag at excessive speeds. To do this, the driving force should first depress the clutch pedal, which disengages the engine from the transmission. Finally, the driving force releases the clutch pedal, Which permits the engine and transmission to reconnect and have interaction. This process have to be repeated each time the motive force desires to vary gears.